- Call Now : +91-1412392501

- E-mail :rpaaa@plynmore.in

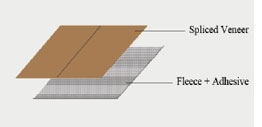

Fleece Backed Veneer

Under high pressure and heat, fleece is affixed to veneers made from all types of wood in a range of sizes. The result is a stable composite material that is significantly easier to work with than ordinary veneer. Even delicate burl veneers are made smooth and even by the applied fleece and are less subject to breaks. The weight of the fleece and the type of adhesive determine the fleeced veneer's stability, strength and resistance to heat and humidity.

Melamine resin bonding, for instance, has greater water and temperature resistance. "MUMSPLY" Fleece & Flex veneers are particularly suitable for multi-dimensional shaping, especially where veneer is glued onto hard-to-work-with surfaces.

But the positive characteristics of fleece & Flex are also appreciated in all conventional areas of application. Thanks to enhancing processing reliability and ease of use, the costs for fleeced veneers can be quickly amortized in most cases.

Salient Features of Fleece 'n Flex:

- Excellent formability and easier to work with

- Can be affixed to various ground work.

- Greater strength

- All spliced veneers can be fleeced

- Fewer rejects in processing

- Fleeced fancy veneers are available in all popular standard sizes

- Fewer works stags; matching and smoothing are done by the manufacturer.

- Wood likes, customized sizes and special effects are possible, and however maximum size available is 2.44 x 1.22 (8'x 4')

- Can be processed with different adhesive systems